Wellcome to asg teknologi indonesia, pt

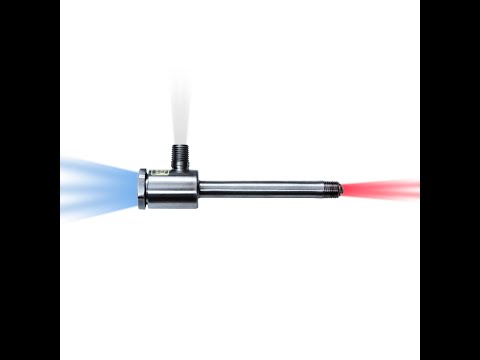

Vortex Tube

What is a Vortex Tube?

The Vortex tube, also known as the Ranque-Hilsch vortex tube, is a mechanical device that divides compressed air into cold and hot streams. The cold streams is an effective, low-cost solution for industrial spot cooling and process cooling applications. Compressed air enters the Vortex Tube and spins at a rate of up to 1,000,000 RPM inside the air chamber. The air travels towards the hot end of the Vortex Tube and once it reaches the end, a small amount is exhausted through a control valve. The remainder of the air is forced back towards the opposite end of the Vortex Tube and it exhausted as cold air. A Vortex Tube can decrease air temperatures by ~115°F (46°C) and raise temperatures by ~200°F (93°C) from the initial air temperature.

How does a Vortex Tube work?

Vortex Tube Applications Examples

There an many Vortex tube applications to efficiently cool products or tooling for industrial manufacturers. Streamtek Vortex Tube products use innovative compressed air technologies to improve productivity, increase equipment efficiency and deliver enclosure and spot cooling, conveying, and blow-off.

What types of Vortex Tubes do we carry?

Streamtek offers two models of Vortex Tube; the 7500 and the 7700 Series.

The 7500 Series Vortex Tubes are engineered to provide optimal temperature drop while maintaining strong air flow.

7700 Series Vortex Tubes are engineered to provide the maximum possible temperature drop while sacrificing some airflow. 7700 Series Vortex Tubes should only be used in special applications where the temperature requirement is below 20°C.

(A) Compressed air, normally 80 to 100 PSIG (5.5 – 6.9 BAR) enters the Vortex Tube through a standard NPTM inlet and tangentially through a generator into the vortex spin chamber.

(B) This air stream spinning at up to 1,000,000 RPM travels in one direction along the small (hot end) tube and then is forced back through the center of this outer vortex.

(C) The brass control valve on the hot end allows for quick n’ easy adjustment of the “cold fraction”; see specifications for what this means.

(D) As the center column travels towards the opposite end, it gives off kinetic energy in the form of heat to the outside stream of air and exits the vortex tube as cold air.

Vortex tube design and air streams.

The Vortex tube design forces compressed air through a generation chamber, which spins the air at a high rate of speed into a vortex. The high-speed air heats up as it spins along the inner walls of the tube toward the control valve. A percentage of the hot, high-speed air is permitted to exit at the valve, resulting in the separation of hot and cold air streams. The hot air can reach temperatures of 200 °C, while the cold air can reach -50 °C.

Cooling electronic controls

Cooling machining operations

Setting hot melts

Cooling soldered parts

Cooling gas samples

Electronic component cooling

Cooling heat seals

Cooling environmental chambers

Maintenance free (No moving parts)

Cools without costly electricity or refrigerants

Reliable, compact and lightweight

Low cost application

Durable – Stainless Steel

Adjustable temperature

Instant cold air

Vortex tube applications